5 Reasons Composite Pallets Are the Backbone of Your concrete block Machine

- Home

- 5 Reasons Composite Pallets Are the Backbone of Your concrete block Machine

When it comes to the concrete block-making industry, efficiency and durability are everything. Every component, from the raw materials to the equipment, must work in harmony to ensure a smooth production process. One often overlooked but critical component in this ecosystem is the pallet. Specifically, composite pallets are proving to be a game-changer for concrete block machines. In this blog, we’ll explore the top 5 reasons composite pallets are indispensable for your concrete block machine operation.

1. Unmatched Durability

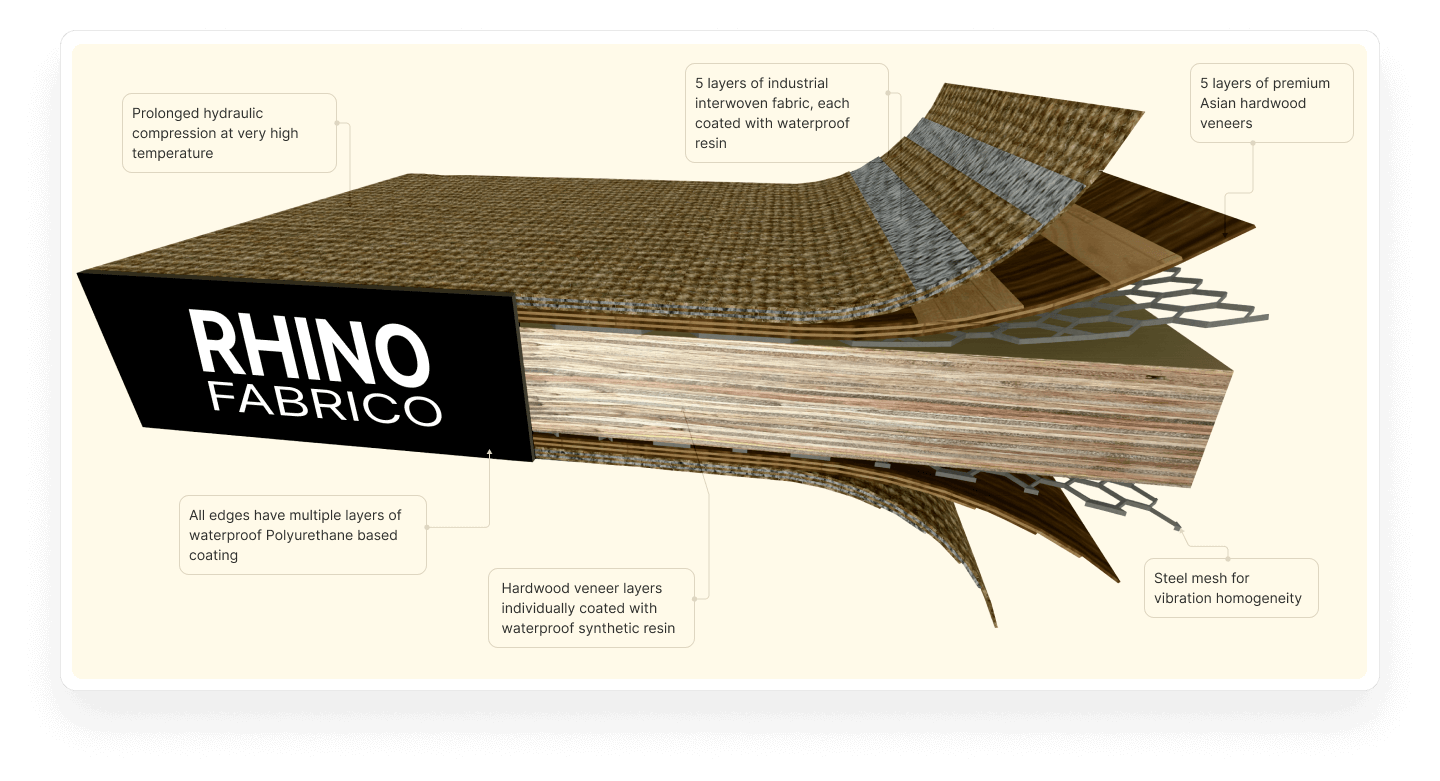

Composite pallets are designed to withstand the rigors of heavy-duty concrete block manufacturing. Unlike wooden or steel pallets, composite pallets are made from hardwood and have steel mesh reinforcement that offer superior strength and resilience. Some composite pallets have a surface protected with plastic for extra protection

- Impact Resistance: Composite pallets can endure the constant impact of heavy concrete concrete blocks being placed and removed without cracking or breaking.

- Weather Tolerance: These pallets are impervious to moisture, extreme heat, and cold, making them ideal for indoor and outdoor operations.

- Longevity: With a lifespan that often exceeds that of traditional pallets, composite pallets save costs in the long run. Plus, RHINO pallets are refurbishable so they last even longer!

The durability of composite pallets ensures consistent production without interruptions, helping you meet your deadlines and maintain customer satisfaction.

2. Enhanced Precision and Stability

Precision is crucial in concrete block-making. Even the slightest deviation in the size or weight of a concrete block can affect its quality and structural integrity. Composite pallets excel in this regard.

- Dimensional Accuracy: Unlike wooden pallets, which can warp over time, composite pallets retain their shape and dimensions even after prolonged use.

- Uniform Surface: The joint-free smooth and consistent surface of composite pallets ensures that concrete blocks are perfectly aligned during curing.

- Load Stability: These pallets are engineered to handle the weight of multiple concrete blocks without bending or sagging, ensuring uniformity in production.The steel mesh reinforced core ensures even load distribution.

By providing a stable and precise platform, composite pallets help manufacturers produce high-quality concrete blocks that meet industry standards.

3. Cost-Effective in the Long Run

While composite pallets may have a higher upfront cost than wooden pallets, they are more affordable than steel pallets and also prove to be more economical over time.

- Reduced Maintenance Costs: Composite pallets do not splinter or rust.

- Fewer Replacements: Their long lifespan means you won’t need to replace them as often as other types of pallets.

- Refurbishable: In addition to an already long lifespan, RHINO composite pallets can be refurbished to near new condition with 5 year additional warranty.

- Lower Downtime: Durable pallets reduce production interruptions caused by pallet failures.

Investing in composite pallets is a smart financial decision that offers significant returns through reduced operational costs and improved productivity.

4. Eco-Friendly and Sustainable

In today’s environmentally conscious world, businesses are looking for ways to reduce their carbon footprint. Composite pallets align perfectly with this goal.

- FSC certified: RHINO composite pallets are Forest Stewardship Council (FSC) certified meaning we source are hardwood from plantations that are managed sustainably.

- Sustainability: Their long lifespan means fewer pallets are discarded, reducing landfill waste.

Using composite pallets demonstrates your commitment to sustainability, which can enhance your brand’s reputation among eco-conscious customers.

5. Compatibility with Modern concrete block Machines

As concrete block-making technology evolves, manufacturers need components that can keep up with advanced machinery. Composite pallets are engineered to be compatible with modern concrete block machines.

- High-Performance Design: Composite pallets can handle the rapid cycles of automated concrete block machines without deforming or failing.

- Low Friction: The smooth surface of these pallets reduces friction during concrete block transfer, ensuring seamless operation.

- Customizable Options: Many composite pallets can be tailored to fit specific machine models, ensuring optimal performance.

By integrating seamlessly with advanced concrete block machines, composite pallets help manufacturers stay ahead of the competition.

Additional Benefits of Composite Pallets

Apart from the five core reasons mentioned above, composite pallets offer several other advantages:

- Hygienic: They are resistant to mold, mildew, and bacteria, ensuring a clean production environment.

- Lightweight: Despite their strength, composite pallets are lighter than steel pallets, making them easier to handle.

- Aesthetic Appeal: Their sleek and modern design adds a professional touch to your manufacturing setup.

Choosing the Right Composite Pallets for Your concrete block Machine

Not all composite pallets are created equal. When selecting pallets for your concrete block machine, consider the following factors:

- Load Capacity: Ensure the pallet can handle the weight of your concrete blocks.

- Machine Compatibility: Check if the pallet dimensions match your concrete block machine’s specifications.

- Material Quality: Opt for pallets made from high-grade materials for maximum durability.

- Supplier Reputation: Choose a trusted supplier with a proven track record of delivering high-quality pallets.

Conclusion

Composite pallets are more than just a platform for your concrete blocks; they are an integral part of your concrete block-making process. Their durability, precision, cost-effectiveness, eco-friendliness, and compatibility with modern machines make them the backbone of any efficient concrete block manufacturing operation.

Investing in composite pallets is not just about improving production; it’s about future-proofing your business. With the right pallets, you can achieve higher efficiency, lower costs, and superior concrete block quality—all while contributing to a sustainable future.

So, if you’re still using outdated pallet solutions, it’s time to make the switch. Your concrete block machine deserves the best, and composite pallets deliver nothing less. Upgrade today and experience the difference!

+614 2193 1745

+614 2193 1745