Pallets for concrete block machines

Best Manufacturer, Global Suppliers & Exporter of Pallets for Concrete Block Production Machines.

- 24 hour service

- High quality production boards

- Variety of pallets

- Durable & refurbishable

+25 years of industry experience

5 year warranty

Refurbishable to near new condition

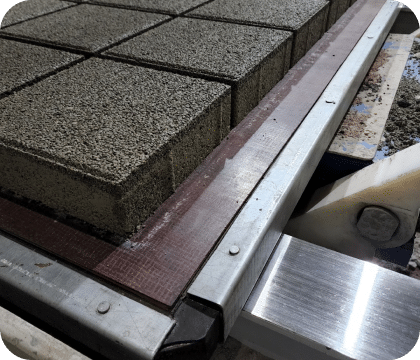

Galvanised steel C-panel available on request

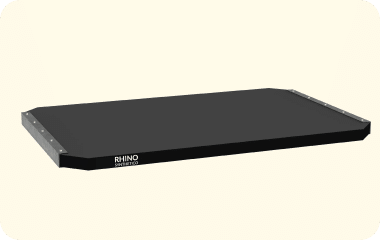

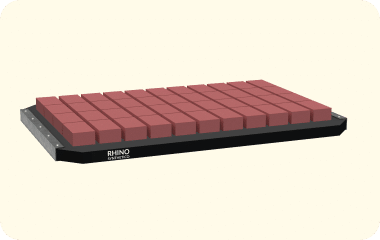

Concrete Block Production Pallets

RHINO Composite Pallets are the ultimate foundation for your concrete block machines, crafted to deliver exceptional durability and precision for businesses. Engineered with the combined strengths of hardwood, steel, and resin, our production pallets for concrete blocks guarantee smooth process, improved efficiency, and a significantly longer lifespan compared to traditional options. Whether you operate on a small scale or manage large industrial operations, RHINO Composite Pallets offer the perfect blend of strength, durability, and reliability.

We provide a 5-year warranty on our brand-new production boards, along with an additional 5 years when you refurbish your RHINO boards with us, ensuring extended service life and unmatched value.

Why Rhino Composite Pallets for Concrete Block Production Machines?

At RHINO, we are your trusted solution for premium-quality pallets for concrete blocks production, meticulously crafted from densified hardwood with a steel mesh core to endure the toughest working conditions.

With over 25 years of global industry expertise, we deliver durable, refurbishable, joint-free boards that provide superior performance and longevity, tailored to excel in unique environmental conditions. Ideal for manufacturing and transporting wet concrete blocks, our production boards are perfect for precast concrete products.

Pallets for a variety of concrete block manufacturing products

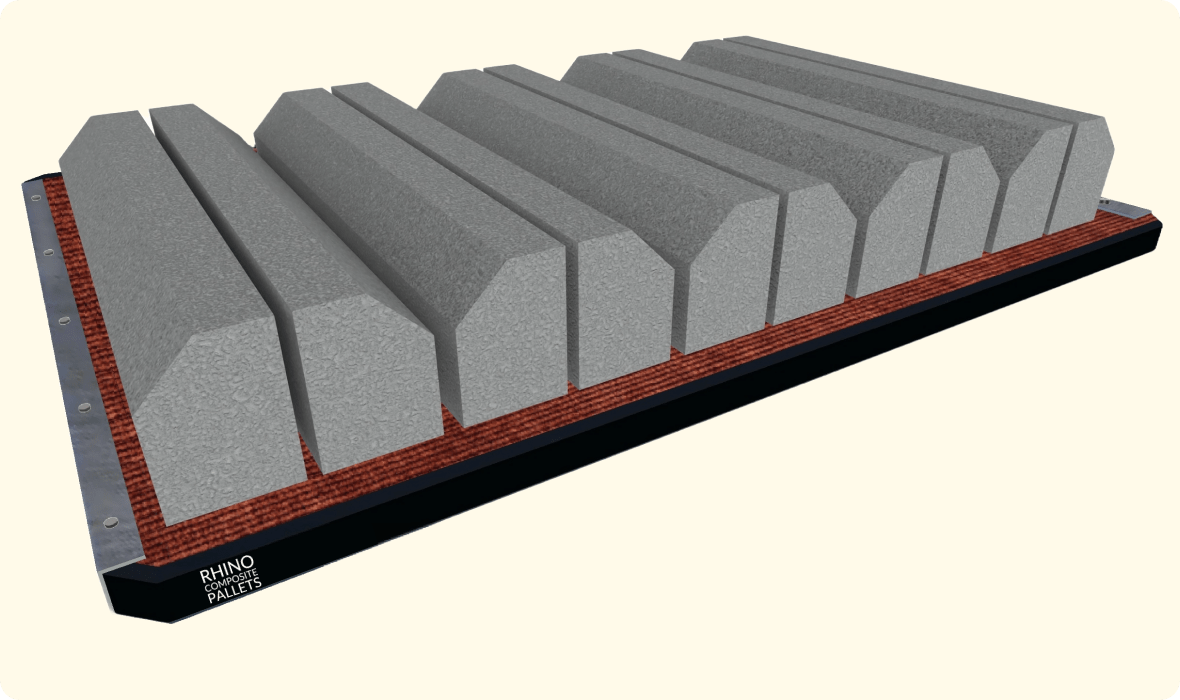

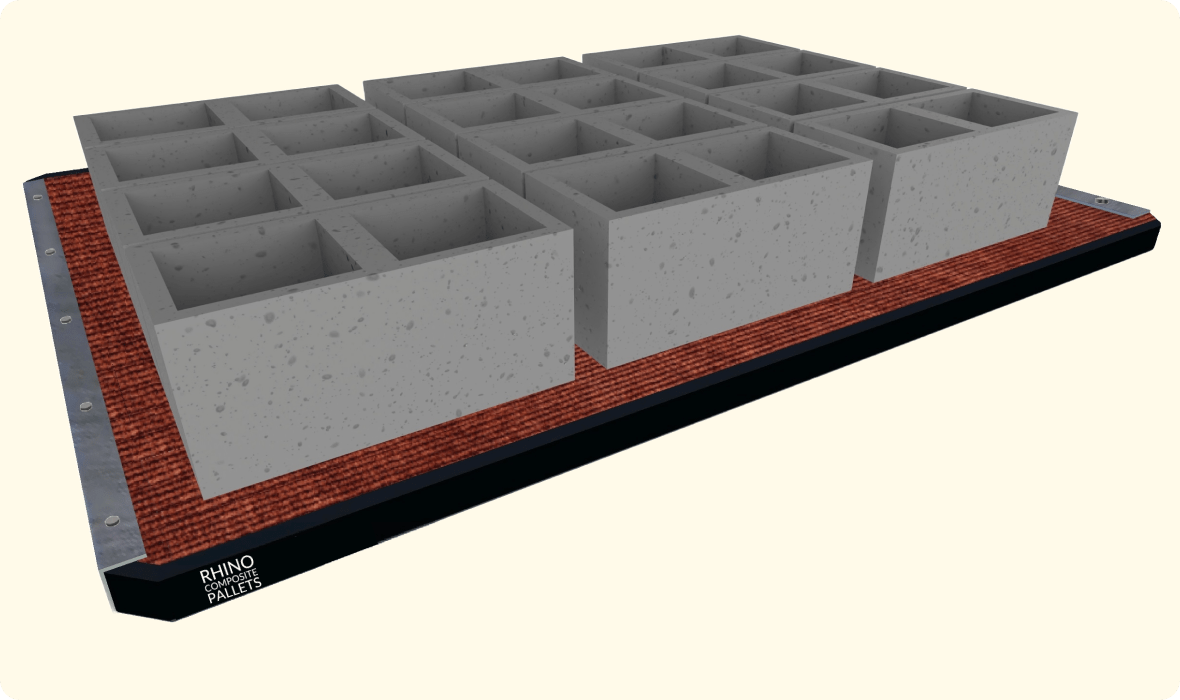

Brick Production Pallets

Sturdy and reliable pallets designed to support high-volume brick manufacturing.

Kerbstones Production Pallets

Heavy-duty pallets built to handle the weight and shape of kerbstones.

Block Production Pallets

Engineered for durability, perfect for seamless concrete block production.

Paver Production Pallets

Built for precision, these pallets ensure smooth and efficient paver production.

hollow block Production Pallets

Strong and stable pallets to maintain the integrity of hollow blocks.

Long lasting pallets = long term savings

Abrasion Resistant

The pallet surfaces are protected with multiple types of abrasion resistant laminations so you can enjoy them for longer.

Denisfied Hardwood

Our pallets for concrete block machine can be densified under 3,300MT of hydraulic pressure to density of up to 1,110 kg/m3. (Softwood 350-500 kg/m3)

RENEW TO NEAR NEW CONDITION

Types of Pallets for concrete block making machines

RHINO Composite Pallets offer a range of premium pallets tailored for concrete block-making machines, including Rhino Fabrico, Rhino Synthetico, and Rhino Plastico. These pallets are crafted using high-quality densified hardwood cores, reinforced with industrial-grade materials like fabric, synthetic films, or polypropylene sheets. Designed for durability and performance, they feature waterproof thermosetting resin coatings and advanced reinforcement for long-lasting use in demanding conditions.

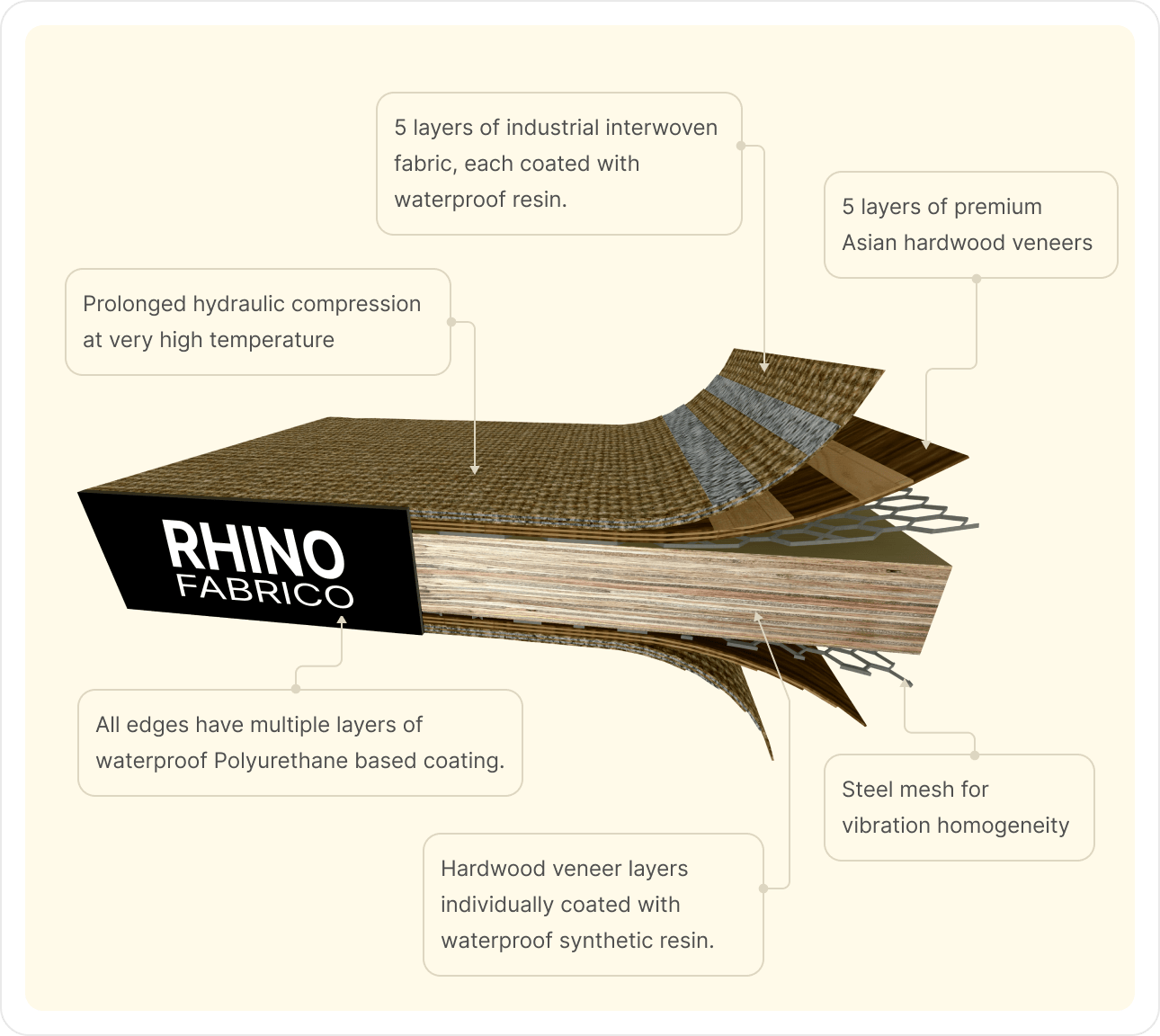

Rhino Fabrico

Premium hardwood pallets with industrial fabric protection

The top and bottom surfaces of this premium densified hardwood pallet are protected by five layers of industrial fabric. The fabric is impregnated with high strength thermosetting waterproof resin.

Rhino Synthetico

Densified hardwood pallet with synthetic film protection

The top and bottom surfaces of this densified hardwood pallet are protected by layers of multiple synthetic films coated with high-strength thermosetting waterproof resin.

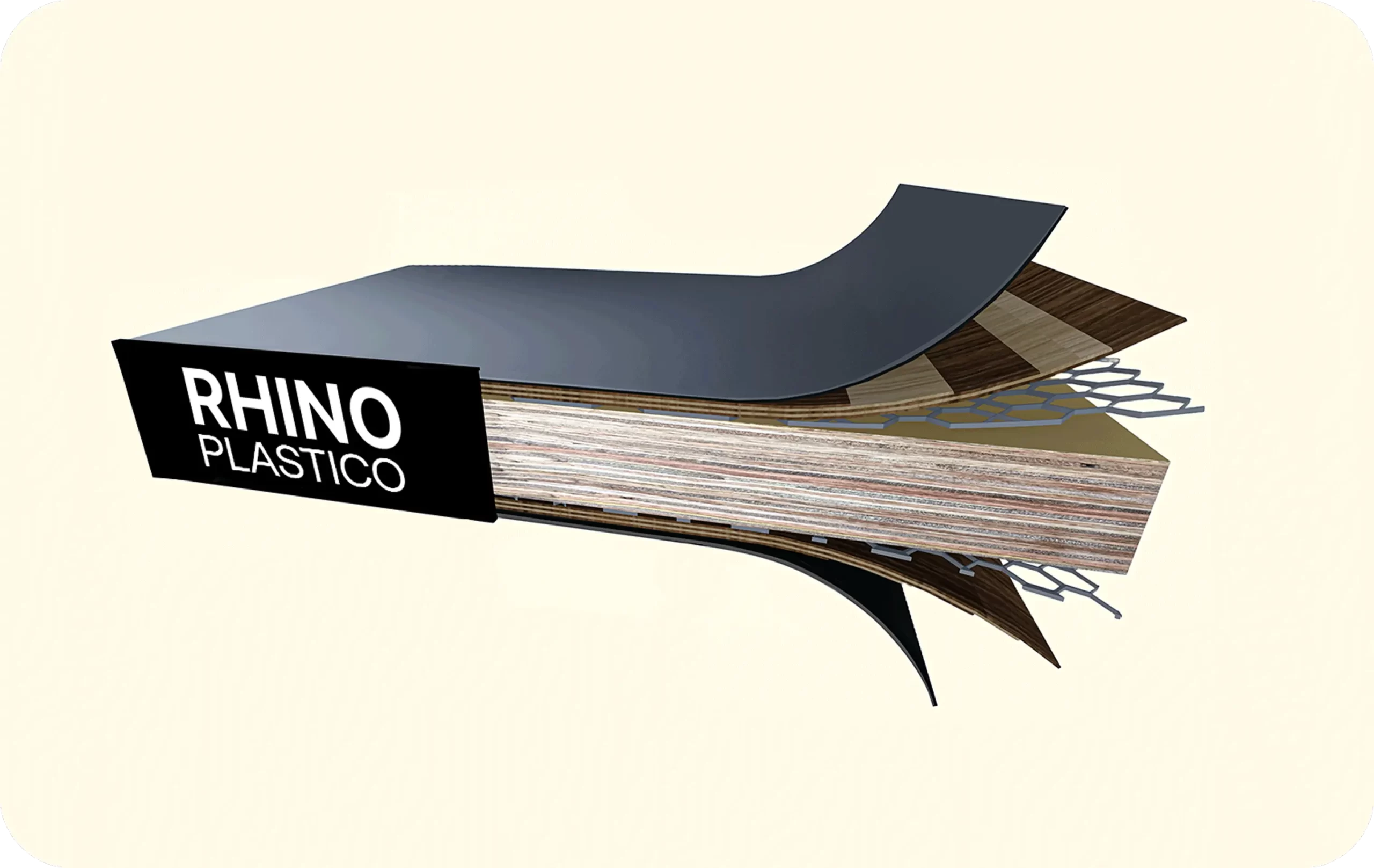

Rhino Plastico

Hardwood pallet with polypropylene sheet protection

The top and bottom surfaces of this plantation hardwood pallet are protected by thick polypropylene sheets. Featuring a densified hardwood core, steel mesh reinforcement, waterproof resin, and a completely refurbishable design.

Our composite pallets can be used with the following concrete machines and many more! Reach out to us for a custom quote.

All trademarks and logos are owned by their respective owners and we do not claim any association with any of these companies.

Visit Our Factory and Explore Our Concrete Block Pallets

We provide high-quality pallets in multiple sizes, perfectly tailored for your concrete block machines. Whether you need pallets for pavers, bricks, blocks, or kerbstones, we’ve got you covered. Our pallets are built for durability, ensuring smooth and efficient production. Plus, we offer worldwide shipping, so you get exactly what you need, wherever you are. Experience hassle-free ordering and top-notch service with us.

Get the perfect blocks. Every time.

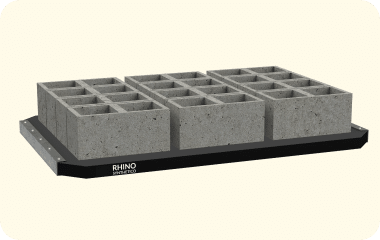

UNIFORM DENSITY OF BLOCKS

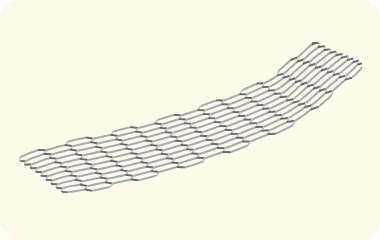

Our high density pallets for concrete block machines are reinforced with steel mesh ensuring sufficient vibration transmission to the fresh concrete every time to ensure uniformity.

UNIFORM HEIGHT OF BLOCKS

RHINO pallets for concrete block machines display minimal deflection even with the heaviest concrete elements, thanks to their technological superiority.

STRUCTURAL SPECIFICATIONS

Our production boards for concrete block machines perform better than steel, softwood or plastic. The unique densified structure coupled with steel mesh reinforcement ensures efficient vibration transmission to the fresh concrete.

High Density (1,000kg/m3)

Long lasting performance and higher load capacities due to the use of densified hardwood and waterproof synthetic resin under high temperature and pressure.

Minimal Deflection

Steel reinforcement offers the pallets strong structural stability and minimal deflection.

Vibrational homogeneity

Steel mesh ensures vibrations are transmitted uniformly through the fresh concrete blocks.

Waterproof Resin

Use of waterproof resin increases longevity.

Available in all Sizes

All sizes required for pallets for concrete block machines are offered, with a maximum thickness of up to 70mm.

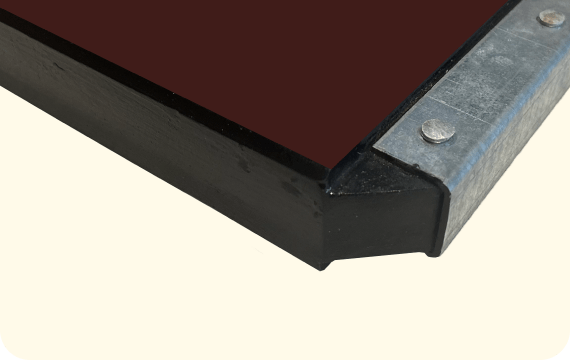

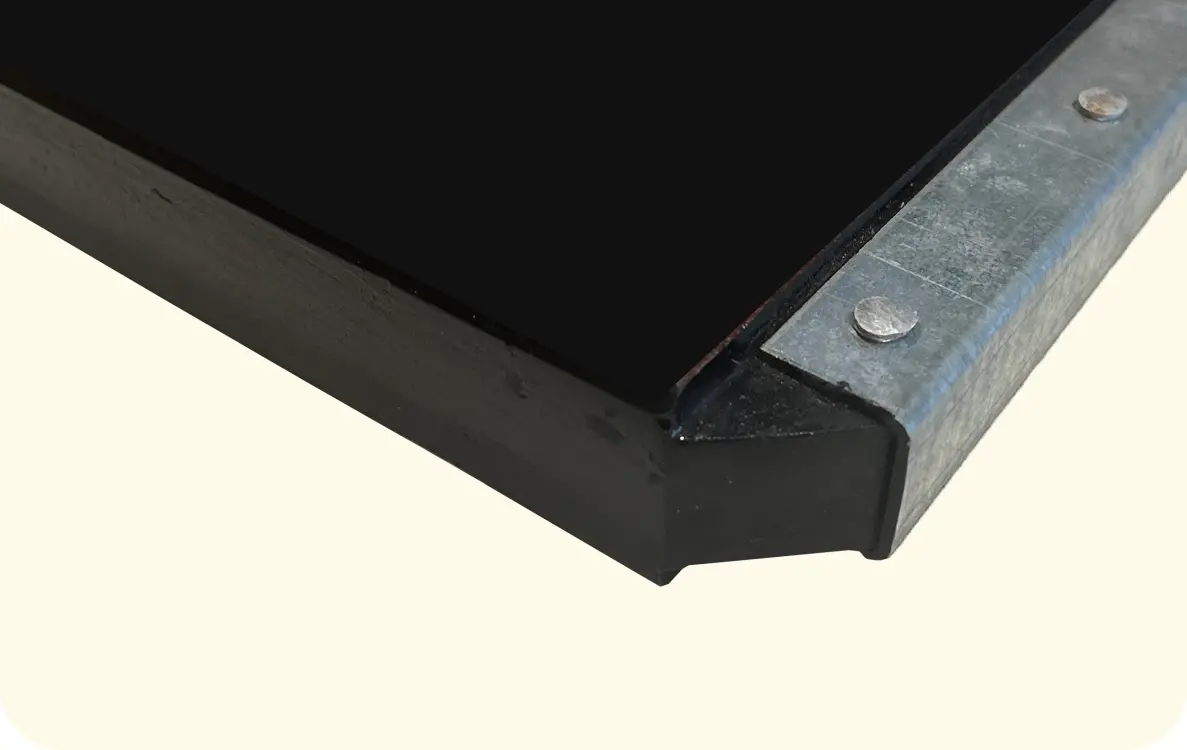

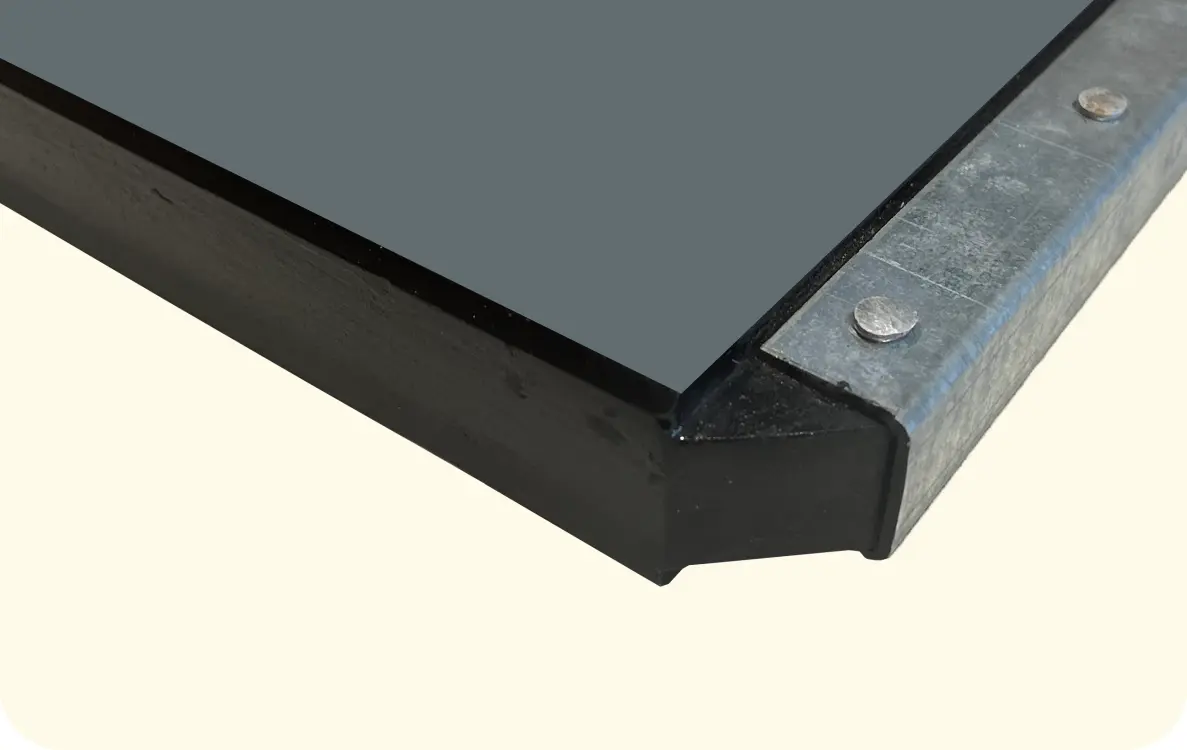

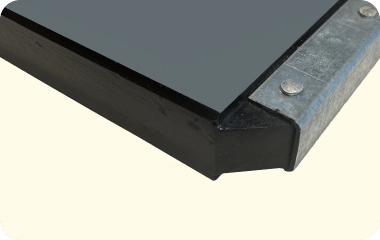

Edge Protection

Our pallets have chamfered edges that minimise physical wear and tear along the corners. The pallets’ edges are further strengthened and protected from physical and moisture damage thanks to our innovative polyurethane impregnated edges.

Refurbishable

The top and bottom layers of all our hardwood pallets can be sanded back up to 3 times to renew the pallet!

PRODUCT FEATURES

Core

The core is made from compressed multi-layered hardwood veneers.

These veneers are cross-laid for extra strength. The final thickness of the pallet decides the number of layers.

DOUBLE STEEL REINFORCEMENTS

Both sides of the pallets have a steel mesh reinforcement, one above the core and another below the core.

This ensures equal vibration distribution over the complete area in touch with the vibration table of the concrete block machine.

SURFACE

The top and bottom surfaces are protected by a thick sheet of polypropylene, industrial strength fabric or multiple layers of synthetic films depending on your choice. This increases the abrasive-resistant properties of the concrete block machine pallets production boards to produce uniform concrete blocks.

PROTECTION

To avoid physical damage to the hardwood pallets, the corners are saw cut and the edges are chamfered.

All sides are further impregnated with a waterproof polyurethane based coating ensuring moisture absorption resistance.

PROLONGED LIFESPAN

At the end of its lifespan, the hardwood pallets’ top surface can be sanded to renew the pallet and last you another few years!

DIMENSIONS

Pallets in all dimensions can be manufactured. Available in thickness between 25 – 70mm.

Quadruple the lifespan

REFURBISHING THE PALLETS

The top and bottom layers of all our hardwood production pallets can be sanded back up to 3 times to renew the pallet! After three sandings, the lamination will be removed and the core will be brought to the surface.

At the end of its service life, simply contact us and we’ll get the pallets shipped back to our factory for a full refurbishment at a fraction of the price of new pallets. The pallets will be restored to a near new condition in a precise refurbishing process. The pallets will then be shipped back to you.

Locations Where We Can Export Pallets for Concrete Block Machines

We provide high-quality pallets for concrete block machines to manufacturers worldwide, ensuring durability, efficiency, and compliance with regional industry standards. Our export locations are as follows:

Questions on Pallets for Concrete Block Making Machine

What is a Block and Brick Making Machine Pallet?

A block and brick making machine pallet is a specialized rectangular platform used in concrete block and brick manufacturing machines. These pallets support freshly molded bricks, blocks, pavers, kerbstones, and other concrete products during the curing and drying process. The right pallet ensures stability, prevents warping, and enhances the overall efficiency of the manufacturing process.

Why Do You Need Concrete Block Pallets?

Concrete block pallets are essential in brick and block manufacturing for several reasons:

- Support & Stability – They provide a flat and sturdy surface to hold fresh concrete products, preventing deformation.

- Efficient Curing – Proper pallets help maintain the shape of bricks and blocks during curing.

- Production Efficiency – The right pallet speeds up production and minimizes defects.

- Durability – Quality pallets withstand heavy loads and prolonged usage.

- Cost-Effective – Long-lasting pallets reduce replacement costs and improve overall operational efficiency.

Do All Types of Brick Machines Need to Be Equipped with Block Pallets?

Yes, almost all brick and block making machines require pallets. Without them, freshly molded concrete blocks would not have a stable base to retain their shape during curing. Different machines may need specific types of pallets based on production requirements, block sizes, and material preferences.

What Are the Specifications of the Pallet?

The specifications of the pallet depend on your manufacturing machine and your preferences. They depend on the desired material, size, thickness, and weight capacity required for your production. For detailed technical specifications, please reach out to us or visit: 🔗 Technical Specifications

How Many Types of Block Machine Pallets Are There?

Block machine pallets vary based on material and production requirements. The common types include:

- Wooden Pallets – Traditional and cost-effective but less durable.

- Bamboo Pallets – Stronger than wood but prone to moisture damage.

- PVC Pallets – Resistant to moisture and chemicals but expensive.

- GMT Fiber Pallets – Durable and lightweight but costlier.

- Hardwood Pallets – The best balance of durability and affordability, offered by Rhino Composite Pallets.

What is a Softwood Pallet?

A softwood pallet is a traditional and economical option made from softwood trees. It is widely used in block-making but tends to absorb moisture and may degrade faster compared to modern composite materials. It requires a consistent level of moisture to function at optimal level so it may not suit arid environments.

What is a Bamboo Pallet?

Bamboo pallets are an alternative to wooden pallets, offering better strength and durability. However, they can absorb moisture over time, leading to warping and reduced lifespan.

What is a PVC Pallet?

What is a GMT Fiber Pallet?

What Are the Advantages of Hardwood Pallets?

Hardwood pallets, like Rhino Composite Pallets, offer the best combination of quality and cost-effectiveness. Their benefits include:

✔ High Strength & Durability – Can withstand heavy loads without warping.

✔ Long-Lasting – More resistant to wear and tear compared to wooden or bamboo pallets.

✔ Cost-Effective – Affordable while offering superior performance.

✔ Moisture Resistant – Less likely to absorb water, reducing the risk of damage.

✔ Suitable for All Block Types – Works well for bricks, hollow blocks, kerbstones, and more.

How to Choose the Right Concrete Block Pallet?

To choose the right pallet, consider:

✅ Machine Type – Ensure compatibility with your block-making machine.

✅ Material – Hardwood pallets offer the best balance of cost and durability.

✅ Load Capacity – Check the weight each pallet can handle.

✅ Moisture Resistance – Essential for long-term durability.

✅ Budget – Choose based on your production needs and investment capacity.

For expert guidance, check out this resource:

🔗 How to Choose the Right Pallets

Where Can I Buy Brick and Block Making Machine Pallets?

You can purchase high-quality block and brick-making machine pallets from Rhino Composite Pallets, a trusted manufacturer offering durable and affordable solutions. They ship worldwide, ensuring you get the best pallets for your production needs.

How Many Concrete Blocks Can Fit on a Pallet?

The number of blocks per pallet depends on the block size and pallet dimensions. On average:

📌 Standard concrete blocks (400x200x200mm) – Around 90 to 120 blocks per pallet

📌 Hollow blocks – Typically 50 to 70 blocks per pallet

📌 Pavers – Can range from 200 to 500 per pallet, depending on size

For precise details, visit 🔗 Technical Specifications or contact us.

Questions on Rhino Composite Pallets

How Does RHINO Composite Pallets Ensure the Quality of Its Pallets?

Rhino Composite Pallets maintains top-notch quality through:

✔ Premium Materials – Made from high-strength, durable composites like resin and steel to withstand heavy loads.

✔ Advanced Manufacturing – Precision engineering ensures consistency in every pallet.

✔ Strict Quality Control – Each pallet undergoes rigorous testing for durability, moisture resistance, and load-bearing capacity.

✔ Customer Feedback & Improvement – Continuous innovation based on real-world user experience.

✔ Industry Standards Compliance – Pallets meet global standards for block and brick production.

What Transportation Options Are Available?

RHINO Composite Pallets offers Sea Freight for all orders. We work with reliable shipping partners to ensure safe and timely deliveries worldwide.

How Long Does Delivery Take on Average?

Delivery times depend on the location of our closest sea port.

For exact delivery timelines, RHINO Composite Pallets provides estimated shipping schedules before dispatch.

How Does RHINO Composite Pallets Assist with Customs Clearance for International Orders?

Rhino Composite Pallets ensures smooth customs clearance by:

✔ Providing Complete Documentation – Includes invoices, packing lists, and certificates.

✔ HS Code & Compliance – Ensuring all products meet import regulations.

✔ Collaboration with Freight Forwarders – Works with global shipping experts to handle customs smoothly.

✔ Customer Support – Assisting buyers with any queries or additional requirements for clearance.

Customers can also get guidance on duties, taxes, and necessary permits based on their country.

How Long Is the Warranty on RHINO Composite Pallets?

Rhino Composite Pallets offers a comprehensive warranty to ensure long-term reliability:

📌 Standard Warranty – Up to 5 years against manufacturing defects.

📌 Extended Warranty on Refurbished boards – An additional 5 years of warranty offered on your refurbished RHINO production boards.

In case of any defects or concerns, please reach out to us and we will rectify the problem as soon as possible.

+614 2193 1745

+614 2193 1745