Why Hardwood Composite Pallets Outlast Traditional Options in concrete block Making

- Home

- Why Hardwood Composite Pallets Outlast Traditional Options in concrete block Making

When it comes to concrete block-making processes, the durability and efficiency of every component in the production line play a critical role. One of the most overlooked yet vital elements is the choice of pallets. While traditional pallets have served their purpose for decades, advancements in technology have introduced hardwood composite pallets, which have quickly become the preferred choice for concrete brick production lines. But why exactly do hardwood composite pallets outlast traditional options? Let’s dive into the details.

Traditional Pallets vs. Hardwood Composite Pallets

Traditional Pallets

Traditional pallets, often made from solid wood or softwood, have been used in concrete block-making for years. These pallets are affordable and readily available, making them an easy choice for many manufacturers. However, their limitations become apparent over time:

- Moisture Absorption: Wood is naturally porous, leading to warping, swelling, or cracking when exposed to moisture.

- Limited Durability: The constant pressure from heavy concrete concrete blocks and the wear from machines often result in short lifespans.

- Inconsistent Quality: Not all traditional wood pallets are created equal, leading to inconsistencies in performance and reliability.

Hardwood Composite Pallets

Hardwood composite pallets, on the other hand, are engineered to overcome the shortcomings of traditional wood. Made from high-density hardwood fibers and advanced resins, these pallets are designed specifically for the demands of concrete brick production lines. Their advantages include:

- Exceptional Durability: Resistant to moisture, high pressure, and mechanical wear, composite pallets last significantly longer.

- Dimensional Stability: They maintain their shape and structural integrity, even under extreme conditions.

- Consistent Quality: The manufacturing process ensures uniform strength and performance across all pallets.

- Eco-Friendly Option: Many hardwood composite pallets are made from recycled materials, reducing their environmental impact.

INDUSTRIAL SYNTHETIC FILM

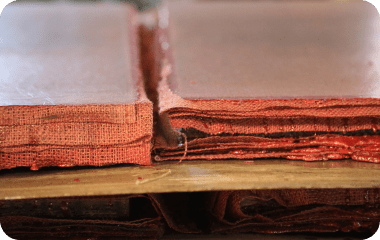

Densified Hardwood

Standard Inclusions

How to Choose High-Quality Wooden Pallets for a Concrete Brick Production Line

Choosing the right wooden pallet for your concrete brick production line is crucial for efficiency and cost-effectiveness.

Ensure that the pallets have sufficient material strength to withstand the weight and pressure of concrete concrete blocks without deforming, with hardwood composite pallets being a reliable choice for heavy-duty applications.

Moisture resistance is also key, as traditional wood pallets can crack or swell under moisture; composite wood pallets are a better option in this regard. The pallet should be compatible with your concrete block-making machinery, with customization options available for a perfect fit.

Additionally, durable pallets, like hardwood composites, offer low-maintenance solutions and reduce replacement frequency, saving costs over time. For sustainability, consider pallets made from recycled or eco-friendly materials, as composite pallets often meet these environmental standards.

How to Choose a Reliable Manufacturer and Supplier of Wooden Pallets for concrete block Machines

Partnering with a reliable supplier ensures consistent quality and a steady supply of pallets for your production line. Here’s how to identify the best supplier:

Experience and Reputation

Opt for manufacturers with a proven track record in producing pallets for the concrete block-making industry. Rhino Composite Pallets, for example, is a trusted name known for its high-quality products.

Customization Options

A good supplier should offer customization to match your specific requirements. Whether it’s size, thickness, or material composition, flexibility is key.

Certifications and Standards

Ensure the manufacturer adheres to industry standards and holds relevant certifications. This guarantees product quality and performance.

After-Sales Support

A reliable supplier provides ongoing support, including assistance with installation, maintenance tips, and prompt responses to queries.

Customer Reviews and Testimonials

Look for feedback from other concrete block machine owners. Positive reviews about durability, performance, and service quality indicate a trustworthy supplier.

Why Rhino Composite Wooden Pallets Are Well-Received by Concrete Brick Machine Owners

Rhino Composite Pallets have gained widespread acclaim in the concrete block-making industry, and for good reason:

Unmatched Durability

Rhino pallets are crafted using advanced composite technology, ensuring they can handle the rigorous demands of concrete concrete block production. Their resistance to wear, moisture, and mechanical stress significantly outpaces traditional wooden pallets.

Optimized Performance

These pallets provide a smooth and stable surface, which enhances the quality of the concrete concrete blocks produced. Their dimensional stability ensures consistent results, batch after batch.

Cost-Effective Solution

Although the initial investment may be higher, Rhino Composite Pallets offer excellent ROI due to their long lifespan and low maintenance requirements. Manufacturers save on frequent replacements and repairs.

Eco-Friendly Manufacturing

Rhino prioritizes sustainability by using recycled materials in their production process. This commitment to the environment aligns with the values of many modern businesses.

Versatility

Available in various sizes and thicknesses, Rhino pallets cater to the unique needs of different concrete block-making machines. Their adaptability makes them a preferred choice across the industry.

Trusted by Industry Leaders

Many concrete brick machine owners and manufacturers have switched to Rhino Composite Pallets, citing improved efficiency and reduced operational costs as primary benefits.

Conclusion

While traditional wooden pallets have their place in the industry, the advantages of hardwood composite pallets are hard to ignore. Their durability, moisture resistance, and consistent performance make them a game-changer for concrete block-making production lines. By choosing a reliable supplier like Rhino Composite Pallets, manufacturers can enhance their efficiency, reduce long-term costs, and contribute to a more sustainable future.

Whether you’re setting up a new production line or upgrading your existing one, investing in high-quality hardwood composite pallets is a decision that pays off in the long run. Make the switch today and experience the difference they bring to your concrete block-making operations.

+614 2193 1745

+614 2193 1745