TECHNICAL SPECIFICATIONS

Discover what makes our production boards for concrete block machines stand out

- Home

- Technical Specifications

What makes our pallets technically superior?

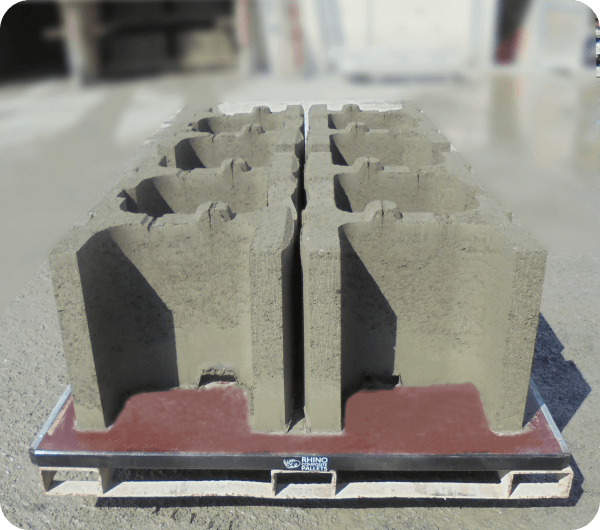

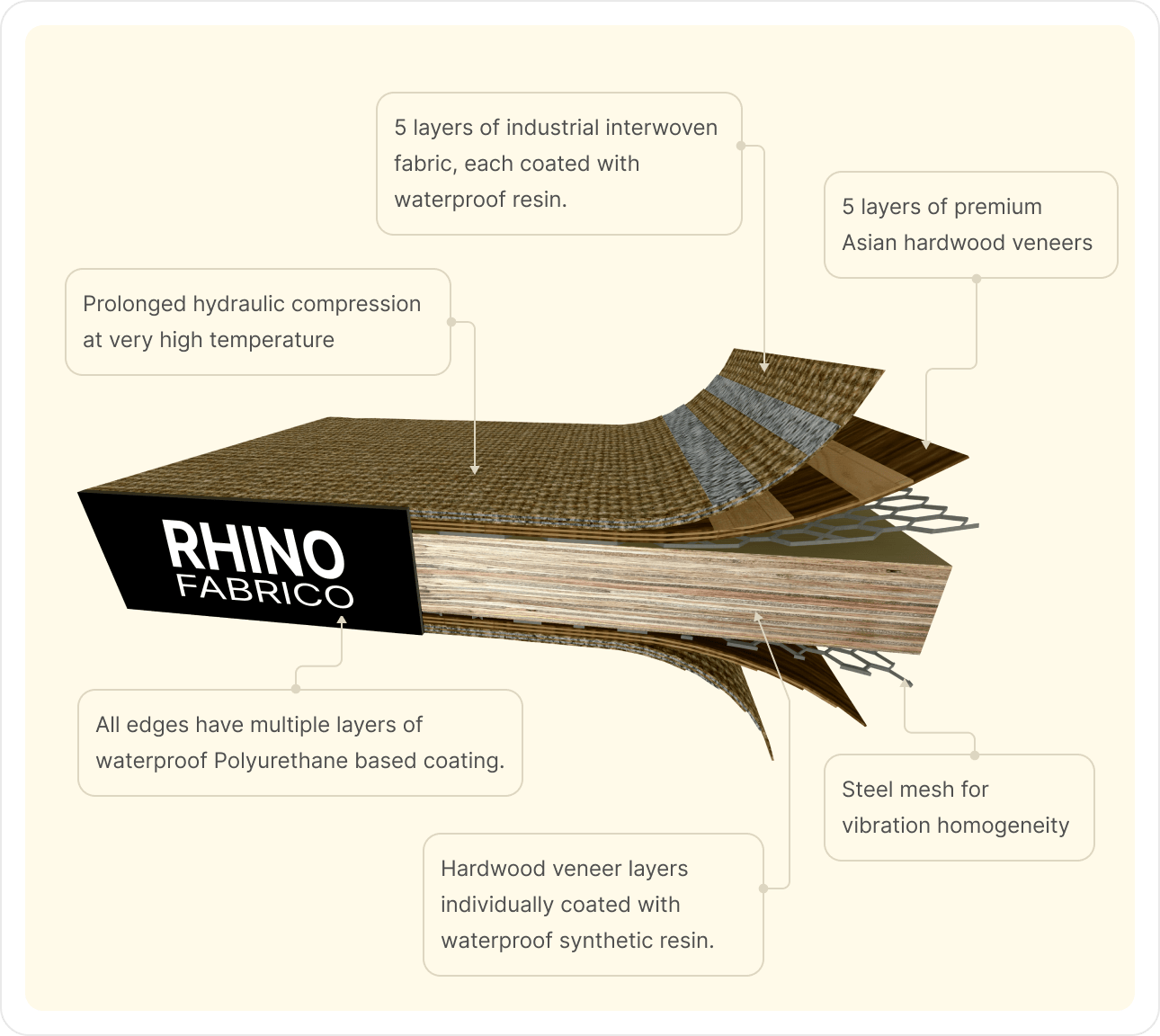

All layers are treated with waterproof resin and pressed under extreme high pressure and temperature. The production boards for concrete block machines are one solid piece, without any joints or gaps. They are laminated with industrial fabric or synthetic film as per your requirements.

Plus, all our pallets can be refurbished to brand new condition!

High Density

Steel mesh reinforcement & high density ensures efficient and uniform transmission of vibrations to fresh concrete.

MINIMAL DEFLECTION

Minimal deflection even at heavy loading due to high pressure and temperature manufacturing technology.

Engineered Surfaces

Moisture and abrasion resistant surfaces ensure that our pallets are long lasting.

BUILT TO LAST

What makes our pallet boards last so long?

Abrasion resistance

Our production boards for concrete block machines are durable against the inevitable abrasion from constant friction from concrete

Renewability

At the end of their life, all our pallets can be refurbished to near new condition, thereby elongating its life span.

Hardwood, not softwood

Unlike softwood, hardwood does not deteriorate rapidly nor does it need frequent replacements.

RENEWABLE TO NEAR NEW CONDITION!

Long term savings when you renew and extend the life of your existing pallets.

All our production boards for concrete block machines come with the following inclusions.

-

Step 01

Step 01Send pallets back to us

After a long and productive service life, send the pallets back to us.

-

Step 02

Step 02Inspection

Pallets will be inspected by our expert engineers

-

Step 03

Step 03Refurbishing

Precise refurbishing process to restore them to near new condition

-

Step 04

Step 04Pallets returned to you

Pallets will be shipped back to you ready for extended use - extending their lifespan even further

-

Step 05

Step 05Enjoy your savings!

Extended service life means huge savings for you at a fraction of the cost of brand new pallets!

STRUCTURAL SPECIFICATIONS

Our production boards for concrete block machines perform better than steel, softwood or plastic when it comes to concrete block production. The unique densified structure coupled with steel mesh reinforcement ensures efficient vibration transmission to the fresh concrete.

High Density (1,000kg/m3)

Long lasting performance and higher load capacities due to the use of densified hardwood and waterproof synthetic resin under high temperature and pressure.

Minimal Deflection

Steel reinforcement offers the pallets strong structural stability and minimal deflection.

Vibrational homogeneity

Steel mesh ensures vibrations are transmitted uniformly through the fresh concrete blocks.

Waterproof Resin

Use of waterproof resin increases longevity.

Available in all Sizes

All sizes required for pallets for concrete block machines are offered, with a maximum thickness of up to 70mm.

Edge Protection

Our pallets have chamfered edges that minimise physical wear and tear along the corners. The pallets’ edges are further strengthened and protected from physical and moisture damage thanks to our innovative polyurethane impregnated edges.

Refurbishable

The top and bottom layers of all our hardwood pallets can be sanded back up to 3 times to renew the pallet!

Manufacturing Process

Plantation Hardwood Timber Selection

Select hardwood is chosen from plantation timbers around the world, ensuring perpetual regrowth of vegetation. Plantation timber is scientifically grown in conducive geographical regions ensuring that the forests are not destroyed for want of wood. All our hardwood is FSC certified for ecological sustainability.

Log Processing

Plantation trees are manually selected to ensure physical parameters of logs. Once selected, the logs go through the process of debarking. Logs are then fed into veneering machines where hydraulically operated sharp blades produce thin layers of timber

Hardwood Veneer Selection

Hardwood veneer forms the core of production pallets for concrete block machines, and thus must be of the highest quality. Veneers with the highest parameters are selected for our pallets. These are then cross laid to increase their core strength.

Humidity Optimised Storage

The veneers’ humidity plays a pivotal role in the final quality of our pallets. Veneers are stored in controlled de-humidifying chambers to achieve the desired level of humidity before proceeding to the next level of manufacturing.

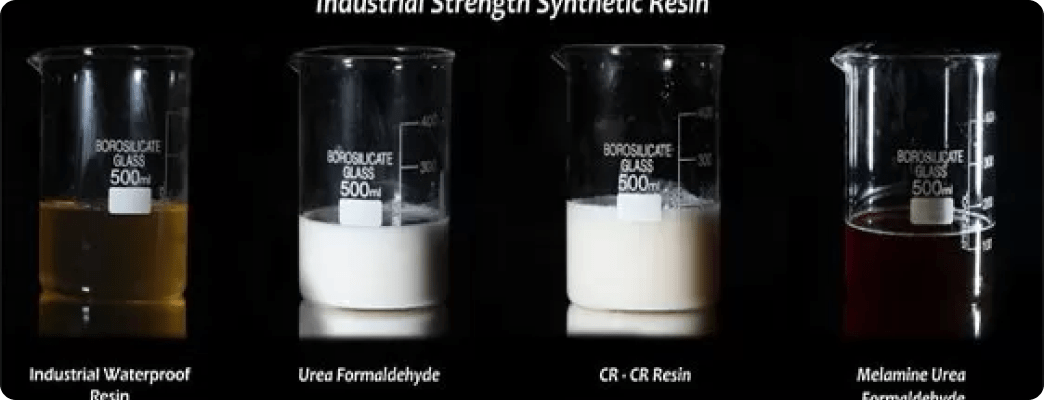

Sourcing Waterproof Synthetic Resin

Onsite manufacturing of industrial strength waterproof synthetic resin ensures consistent quality for different applications. Our production pallets for concrete block machines use the highest grade of waterproof synthetic resin.

Saturating Veneer Fibres with Resin

Individual veneer sheets are rolled through resin ensuring complete fibre saturation. This ensures absolute adhesion during compression using superheated steam producing high quality production pallets.

Hydraulic Compression

Layered to optimum thickness, the production pallets are subjected to 3,300 tonnes of prolonged compression using superheated steam and hydraulic presses. This step ensures desired density and waterproof adhesiveness is achieved.

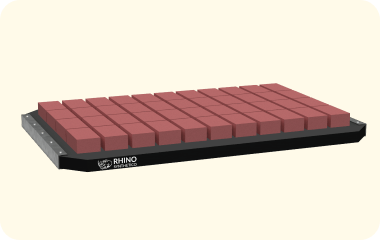

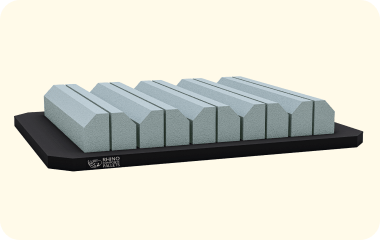

Choice of Board Surfaces

The core is laminated under high temperature and pressure once again with multiple layers of synthetic film or interwoven fabric using waterproof resin, depending on the client’s requirements. This process ensures abrasion resistance thereby increasing product life.

Quality Control

The “Mother Board” thus formed, is cut to size as per our client’s requirements. The production boards for concrete block machines then go through a stringent calibration process on highly sensitive equipment to achieve the required parameters as per our client’s requirements.

+614 2193 1745

+614 2193 1745