Rhino Hardwood Composite Pallets

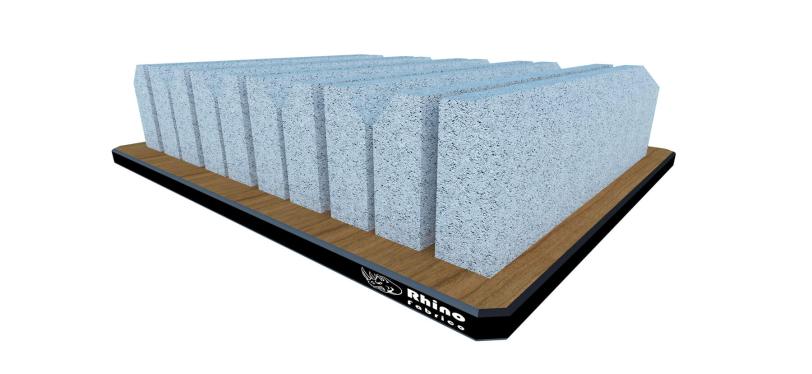

Pallets for Concrete Block Machine

Built to Last

Watch Video

Designed to Last!

RHINO densified hardwood pallets for concrete block machine

Our products are designed and built to last through harsh and abrasive working conditions that pallets for concrete block machine encounter. Our pallets are manufactured with multiple varieties of surfaces to cater individual requirements of concrete block manufacturers around the world. Surfaces of Industrial Fabric and Synthetic Film offer different levels of resistances to the abrasive nature of concrete products. Rhino Composite Pallet for concrete block machines have much better performance than steel, hardwood, softwood or plastic. Densified structure and steel mesh reinforcement ensures efficient transmission of vibration to the concrete. Available in all sizes with thickness upto 70mm.

Thickness upto

Temperature

Compression (MT)

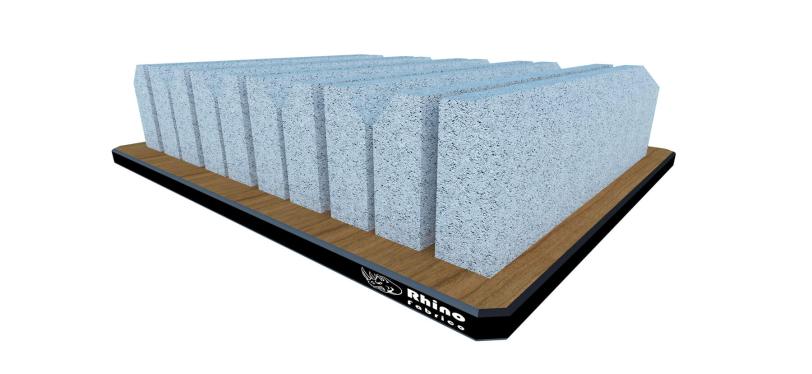

Pallets for concrete block machine

Rhino composite pallets for concrete block machines are designed to last through harsh and abrasive working conditions. They are designed specifically to cater to high dimensional accuracies required for production of pavers, kerbstones, blocks and other concrete products. Our pallets are precisely manufactured in three different varieties to cater to individual requirements of concrete block manufacturers around the world. Surfaces of Industrial Fabric and Synthetic Films offer different levels of resistances to the abrasive nature of concrete productsse

Quality is our benchmark

Rhino Composite Pallets for Concrete Block Machine

High Density Pallets

Minimum Deflection

Renewable Pallets

Benefits of RHINO pallets for Concrete Block Machines

Technologically superior

Manufactured in state of the art Hydraulic Presses and exclusive use of tropical plantation hardwood fibres in manufacturing ensures consistent quality.

Different types of engineered surfaces are offered to protect the inner core of hardwood ensuring long life of trouble free services by the pallets.

Manufacturing flexibility allows all sizes and qualities based on client specifications as per requirement of pallets for concrete block machine.

Our design factors variables like handling systems, product weight, curing room conditionalities, abrasiveness etc. for long pallet life.

3,300 Tonnes of prolonged compression using superheated steam ensures homogeneous densified structure & longlasting performance.

High quality industrial thermosetting resin ensures high density and waterproof adhesiveness of our pallets for concrete blocks.

HighDensity

Ensures Efficient Vibration Transmission

FSC Certified

All the hardwood used in our boards is always FSC certified. Minimises the impact on our jungles.

VIBRATION TRANSFER

Steel mesh & high density ensures efficient and uniform transmission of vibrations to concrete.

ABRASION RESISTANT

Pallet surfaces are protected with multiple types of abrasion resistant films for long life span.

Benefits of

Rhino Composite Pallets

Strong and Homogeneous. Excellent vibration transmission.

Hardwood Fibre Fortification. Faster cycle times.

Less wear to machines. Consistent Compaction.

Made with waterproof resin High block density.

Minimum deflection. Lesser Power Consumption.

Sturdy Pallets with Long life. Vibrational Stress Compatibility.

Latest News

From Our Blog

Effect of Rhino hardwood pallets for concrete paver machine on environment.

Effect of Rhino hardwood pallets for concrete paver machine on…

Test RHINO pallet boards far outlast traditional production pallet for concrete pavers.

Test Blog Evolution in material forms has always been associated…

RHINO pallet boards far outlast traditional production pallet for concrete pavers. Truth or Myth?

Our boards outlast traditional production pallet for concrete pavers. Truth…